In addition, the flue gas formed by burning household garbage also contains countless fine particles. These fine particles continue to accumulate on the heating surface and gradually form a structure similar to the thermal insulation layer, which is extremely unfavorable for the heating surface to absorb the waste heat of the incinerator. Therefore, when recovering and applying the waste heat of the domestic waste incinerator, certain protective measures must be taken for the heating surface to prevent the surface of the heating surface from forming ash.

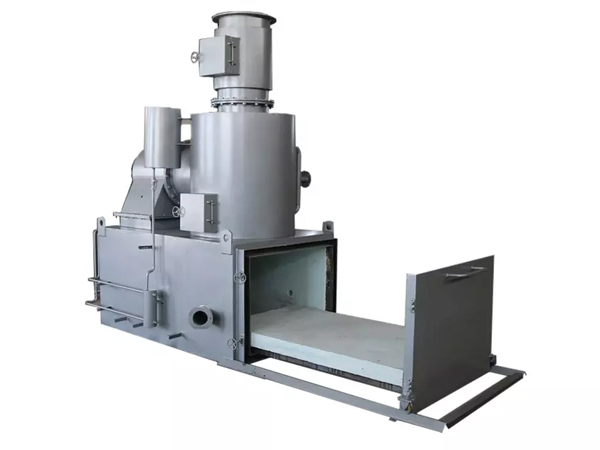

In view of the above problems, the process design of the furnace body is also very important. The furnace body is lined with high temperature refractory material, the middle is heat insulating material, and the outer layer is heat insulating material, which can reduce the heat loss of the furnace body and improve the incineration efficiency; the outer surface is made of steel plate as a protective layer to prevent air leakage. In the furnace, the flue gas flushes the material from bottom to top, and the moisture in the material is dried, so that the material can catch fire in time. In addition, the front and rear refractory materials store heat and radiate the materials, thereby ensuring the combustion temperature of the materials. The residence time of the flue gas is prolonged, the organic matter in the material and fly ash is completely burned, and the destruction rate of harmful substances is improved.