Hazardous waste can be treated by chemical, thermal, biological and physical methods. Chemical methods include ion exchange, precipitation, redox and neutralization. In thermal methods, incineration not only detoxifies some organic wastes, but also destroys them.

Waste to energy incinerator can reduce waste from the production stage, and converting waste into energy through waste to energy incinerator has become the mainstream choice for environmental protection. Its incineration process brings heat and electricity.

Heat generation: This involves simply heating water through waste combustion. The process is energy efficient, recovering 70% to 80% of the heat of combustion after incineration, or about 1,500 kWh of thermal energy per ton of waste. Of course, the heat generated then has to be used somewhere near the device.

Power generation: The heat exchanger must contain steam at the highest possible pressure. This steam is sent to a turbine that drives a generator. The electricity generated can be supplied to the grid year-round. The energy efficiency of this process is about 20% to 25% (300 to 400 kWh).

The

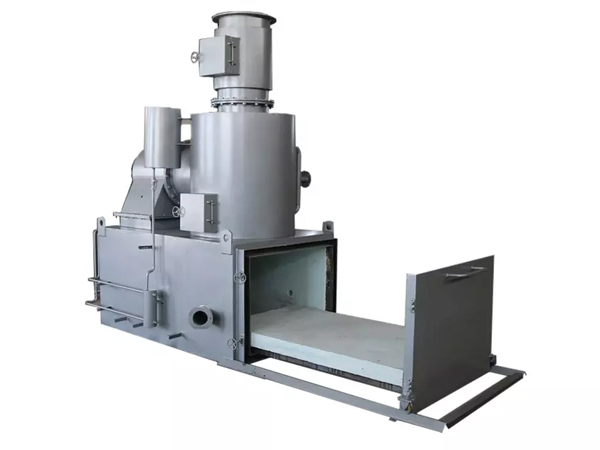

waste to energy incinerator can effectively reduce organic solid waste without adding fuel oil and without electricity to support combustion. It is a real energy-saving product. The utility model has the advantages of simple operation, convenient use, reasonable design and structure, and can easily pour garbage into the furnace body, and the incineration efficiency of garbage is high.

After one ton of garbage is treated, the ash residue can be used for composting in fruit trees and vegetable gardens. The flue gas generated by the incineration is processed by the first and second combustion chambers and fully incinerated, and finally the emission is smoke-free and odor-free, which meets the national standard. The small waste to energy incinerator can process rural domestic waste within 10 tons per day; it occupies a very small area; the operating cost is very low, and no fuel combustion is required after the temperature in the furnace reaches 850 degrees; the equipment has a service life of more than 10 years, and all use high temperature and corrosion resistant materials

If you need such a device, contact

holy shield today to order it! We can also provide product customization services!