At present, the best waste reduction effect is the pyrolysis gasification technology. As a professional waste treatment manufacturer,

Holy Shield will explain its principles and advantages.

Biomass pyrolysis gasification technology combines the fluidized bed semi-coke gasification and biomass hydropyrolysis technology based on the combination of biomass characteristics and rapid pyrolysis device, and takes the circulating fluidized bed staged pyrolysis gasification technology as the At the core, the raw materials are subjected to hydropyrolysis to increase the methane content, thereby increasing the calorific value of the gas, without producing waste water, tar, fly ash and other pollution, rationally utilizing potassium, magnesium and silicon resources to achieve efficient and comprehensive utilization of biomass energy. Its technical principles include: hydrogen pyrolysis technology, semi-coke gasification technology, and gas purification technology. The whole process has no secondary pollution, no exhaust gas emission, and no dioxin generation.Biomass pyrolysis gasification technology combines the fluidized bed semi-coke gasification and biomass hydropyrolysis technology based on the combination of biomass characteristics and rapid pyrolysis device, and takes the circulating fluidized bed staged pyrolysis gasification technology as the core, the raw materials are subjected to hydropyrolysis to increase the methane content, thereby increasing the calorific value of the gas, without producing waste water, tar, fly ash and other pollution, utilizing potassium, magnesium and silicon resources rationally to achieve efficient and comprehensive utilization of biomass energy. Its technical principles include: hydrogen pyrolysis technology, semi-coke gasification technology, and gas purification technology. The whole process has no secondary pollution, no exhaust gas emission, and no dioxin generation.

According to different heating methods, it is divided into direct heating method and indirect heating method.

The direct heating method refers to the direct combustion of the waste part, or providing air, oxygen-enriched or pure oxygen as supplementary fuel to the pyrolysis reactor. Pure oxygen as a catalyst will generate CO?, H?O, which are mixed in the pyrolysis combustible gas, which will dilute the combustible gas and reduce the thermal effect of the pyrolysis gas. Using air as a catalyst contains a large amount of N?, which further dilutes the combustible gas and greatly reduces the calorific value of the pyrolysis combustible gas. Taking the experimental data of American municipal waste as an example, the calorific value of using air as a catalyst is generally around 5500KJ/m³, while that of pure oxygen is generally around 11000KJ/m³.

The indirect heating method can use drywall heat conduction or an intermediate medium for heat transfer. The calorific value can reach 18630KJ/m³, which is equivalent to more than three times the calorific value generated by the direct heating method using air as an oxidant, and can be directly used as gas.

Compared with direct incineration, waste pyrolysis has the following advantages:

(1) During the pyrolysis process, the organic components of the waste can be converted into the form of usable energy, which is more economical; the gas produced by pyrolysis can be directly burned or mixed with other high calorific value fuels depending on its calorific value. The tar produced in the reaction process can be made into fuel or extracted from chemical raw materials depending on its properties.

(2) The secondary pollution of the pyrolysis incineration system is small, which can simplify the pollution control problem and be safer for the environment;the amount of flue gas generated by the pyrolysis method is less than the direct incineration method, especially the heavy metals and dioxins in the flue gas. The content of pollutants is less, which is beneficial to the purification of flue gas and reduces the emission level of secondary pollutants, so it is a safe garbage disposal method. Process composition Pyrolysis process mainly includes moving bed pyrolysis, fluidized bed pyrolysis, rotating bed pyrolysis and so on.

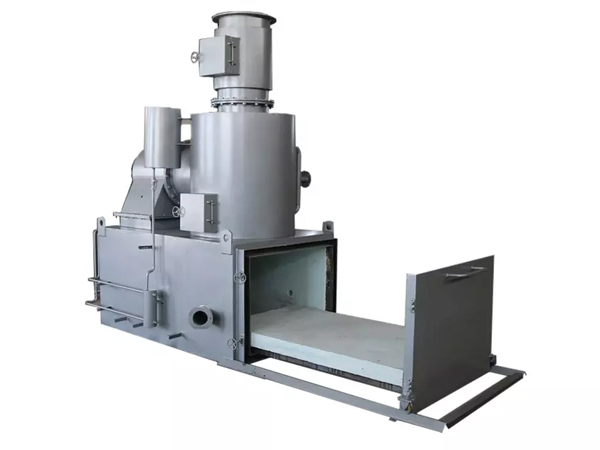

Holy Shield is a professional solid waste treatment equipment manufacturer with rich technology and R&D capabilities. Our

waste incinerator products are easy to operate, environmentally friendly and harmless, reliable in quality, smokeless and odorless, environmentally friendly and energy-saving, and low in cost .