A large amount of smoke and dust will inevitably appear in the garbage incineration process, but the smoke and dust that appear are not allowed to be directly discharged. Therefore, the waste incinerator of Holy Shield must consider this problem in the design and production stage.

In the garbage incineration process, the incinerator filled in the garbage incinerator will produce a large amount of waste gas after being processed by the high-temperature carbonization pyrolysis furnace. The exhaust gas produced mainly includes pyrolysis flue gas and odor. Pyrolysis flue gas pollutants mainly contain acid gas, particulate matter, nitrogen oxides, heavy metals and dioxins, and odor mainly refers to gas with pungent temperature.

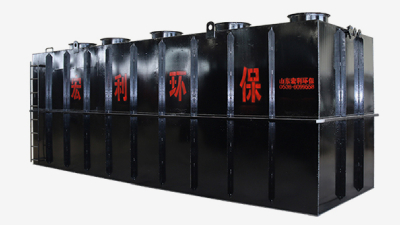

When holy shield designs and produces waste incinerators, it fully considers the handling of smoke and dust. In order not to cause harm to the atmosphere, we use a variety of different process technologies:

The first is the high-temperature pyrolysis gasification technology, which uses high temperature to gasify and incinerate the smoke and dust to achieve the purpose of removing harmful gases such as dioxins.

Secondly, dust removal equipment such as deacidification tower, bag filter, cyclone dust collector is used to filter and intercept the smoke and dust, so as to achieve the effect of smokeless and odorless emission standards.

In general, the

Holy Shield garbage incinerator is a method of cracking harmful gases, recycling or reducing the emission of smoke and dust, to achieve the purpose of protecting the environment and purifying the air.