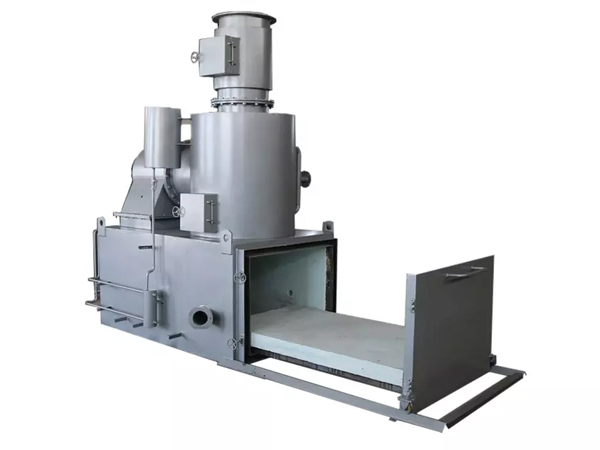

Different small waste incinerators have different operating conditions and different operating temperatures. Therefore, when choosing refractory materials, we need to think more comprehensively. Holy Shield shares a few tips for you.

Different working environments: In the drying chamber and combustion chamber of the waste incinerator, the waste and the furnace lining are in direct contact at high temperature. On the one hand, the slag will adhere to the furnace lining, and on the other hand, impurities will also penetrate into the furnace lining. At the same time, the input of waste will inevitably cause temperature. Therefore, the selection of refractory materials must be wear-resistant, corrosion-resistant, difficult to adhere, and also have alkali resistance and oxidation resistance. High-alumina bricks and silicon carbide bricks can be selected, and high-alumina castables and silicon carbide can be selected for irregular parts. Castables and plastics.

The temperature used is different: the use temperature of the roof, side walls and burners of the combustion chamber is 1000-1200 °C, and it is necessary to choose high-alumina bricks with refractoriness that is all clinker, or high-alumina plastics.

Holy Shield focuses on the production, R&D and customization of waste incinerators. With strong R&D strength, it can transform the performance of incinerators according to the different needs of enterprises and provide more cost-effective product solutions. If you have needs, you can contact us.